- Home

- »

- Fibergrating's Blog

- »

- How to Maximize the Benefits of Fiberglass Handrails Across Multiple Industries?

Table of Contents

Introduction

Fiberglass handrails are highly versatile, widely used across numerous industries thanks to their strength, light weight, and ability to withstand harsh environments. These handrails serve various sectors, offering both practical utility and aesthetic appeal.

Construction and Architecture

Fiber Reinforced Polymer (FRP) composites are extensively utilized in the construction and architectural industries. Architects and contractors use these materials in energy saving windows, thermal barriers, oil and gas pipelines, beams, and cross supports. Their lightweight and weather resistant qualities make them an excellent choice for wind turbine blade components and other construction elements that need to be durable and low-maintenance over time.

Initially employed for building features like roofing and wall panels, FRPs have evolved to become essential in all areas of modern construction. They are now frequently used to enhance building appearances with design elements such as floating roofs and striking facades, making significant contributions to contemporary architecture across the U.S. and worldwide.

Industrial Uses

FRP handrails and structural elements are cost-efficient, thanks to the pultrusion manufacturing process, which produces large quantities at low costs. Compared to traditional materials like steel, FRPs are significantly lighter, reducing shipping expenses and eliminating the need for heavy duty lifting equipment.

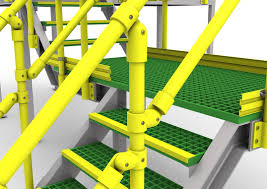

In industrial environments, FRP handrails are installed around operational platforms, such as those surrounding FRP centrifugal fans and purification towers. Their installation requires carefully designed support structures, typically secured with bolts or reinforced through concrete foundations.

Road Traffic and Wind Energy Industries

In the road traffic sector, FRP composites are used in various applications, including highway isolation barriers, road signage, pedestrian bridges, soundproofing walls, and parts of refrigerated trucks.

For the wind energy market, FRP sheets produced through the pultrusion process are used for the main beams in wind turbine blades. These sheets are later integrated into the blades using techniques such as vacuum infusion or prepreg, enhancing the strength and rigidity of the final product, contributing to more efficient and cost-effective wind energy solutions.

Chemical and Consumer Markets

FRP materials are commonly applied in chemically aggressive environments, where they provide structural support in applications such as sucker rods, cooling tower braces, offshore oil platforms, and covers for water treatment facilities. Their resistance to corrosion makes them ideal for these challenging settings.

In the consumer market, FRP materials are used to produce items like fishing rods, tent poles, umbrella frames, flagpoles, tool handles, lighting poles, railings, staircases, and gardening tools.

Environmental and Economic Advantages

The use of FRP in structural applications brings significant cost benefits due to its efficient production and minimal maintenance needs. These handrails can be engineered to exceed OSHA safety standards, with the addition of specialized resins for enhanced fire and heat resistance. Moreover, the growing trend of using recycled materials in FRP production aligns with the increasing focus on sustainability and environmental responsibility.

Contact Us

Ready to enhance your projects with durable and cost effective fiberglass handrails? Contact us today to explore our wide range of FRP solutions and discover how they can add value to your applications. Let’s build a safer, more efficient future together!

Comments

Frequently Asked Question

Fiberglass handrails offer several advantages including lightweight construction, high durability, resistance to harsh environmental conditions, and low maintenance requirements. They are also cost-effective due to their ease of installation and long-term performance.

Fiberglass handrails are widely used in various industries including construction, architecture, manufacturing, road traffic, wind energy, chemical processing, and consumer goods. Their versatility makes them suitable for both industrial and aesthetic applications.

Compared to steel, fiberglass handrails are lighter, reducing shipping and handling costs. They also offer superior resistance to corrosion and environmental wear, leading to lower maintenance needs and a longer lifespan.

Installation involves designing appropriate support structures and securing the handrails through methods such as bolting or concrete embedding. It’s essential to follow proper installation guidelines to ensure stability and compliance with safety standards.