Kind Hold Products

PULTRUDED FIBER GLASS GRATING

Your trusted provider of Fiber Grating solutions

Pultruded Fiberglass Grating – Handling Heavier Loads with Extended Spans

Pultruded Fiberglass Grating offer superior load-bearing capabilities and extended spans compared to similarly sized molded FRP grating.

We provide I-bars, T-bars, and High-Load bars suitable for a wide range of applications, from ADA-compliant walkways to heavy-duty vehicle traffic decking.

For detailed information about the various types, specifications, and availability of our pultruded FRP/GRP grating, please explore our dedicated page.

If you’re interested in purchasing FRP/GRP MOLDED GRATING instead, click for more information.

Pultruded Fiberglass Grating Catagory

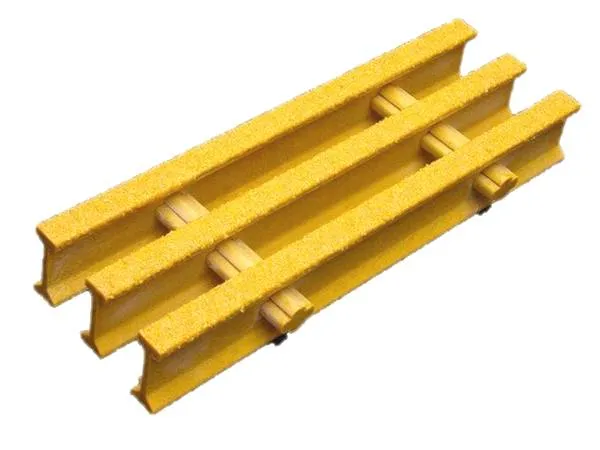

Pedestrian pultruded grating is designed for pedestrian traffic.The gratings are assembled by wide ‘T’bars. They are designed ideally for the application of access areas and walkways. Some of our pedestrian series gratings can comply with ADA (Americans with Disabilities Act of 1990) and DDA (Disability Discrimination Act in UK)

Industrial series grating is designed for wide application of vary industrial area where request high strength and corrosion resistance.

Some type of our industrial series gratings can comply with ADA (Americans with Disabllties Act of 1990)and DDA( Disablity Discrimination Act in UK)

High Load Capacity Pultruded Grating is engineered for forklift,tractor trailer or high load with large spans where the

tradtional pultruded grating is not able to support.Some of our pedestrian series gratings can comply with ADA (Americans

with Disabilities Act of 1990)and DDA (Disability Discrimination Act in UK)

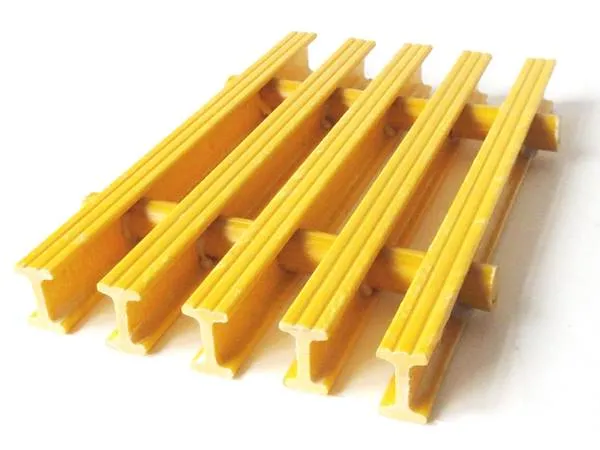

Standard l bar Pultruded Grating, which also called pultruded SI Series gratings suitable for use in pedestrian traffic areas and the 73% and 83% open areas allow for excellent airflow.With profile appearance similar to metal grating, pultruded Sl Series gratings are often used in areas where a close match to a steel or aluminum profile is desired.

Kind Hold Pultruded Fiberglass Grating Features

With over a decade of dedicated experience, we have been committed to delivering highly professional Fiber Grating technology products. We understand that professionalism and experience are the keys to success, and they are at the core of our foundation.

Higher loads

Higher loads and longer span than molded grating.

Corrosion resistance

Excellent chemical and harsh condition resistance.

Lightweight

1/3 lighter than steel grating with the same load ability.

Extended life

The coated resin surface increases resistance to chemical corrosion and continuous UV exposure.

Anti-slipping

Gritted, corrugated or convex surface for safe access.

Easy fabrication

Lightweight structure is easy to fabricate by simple hand tools.

Flame retardant

UV inhibitor for UV resistant and fire retardant..

Stability

Higher loads and corrosion resistance for maximum stability.

Available Bearing Bar Type

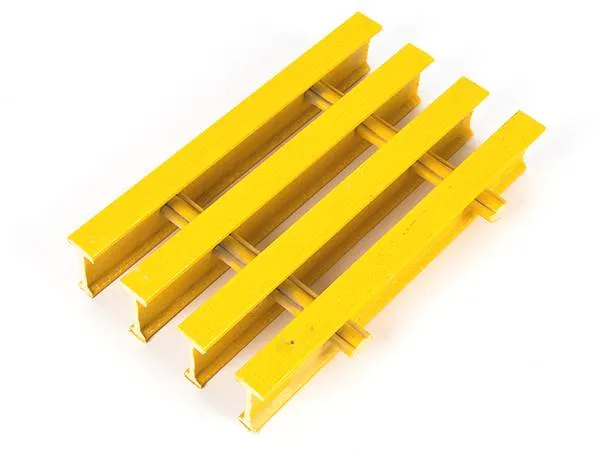

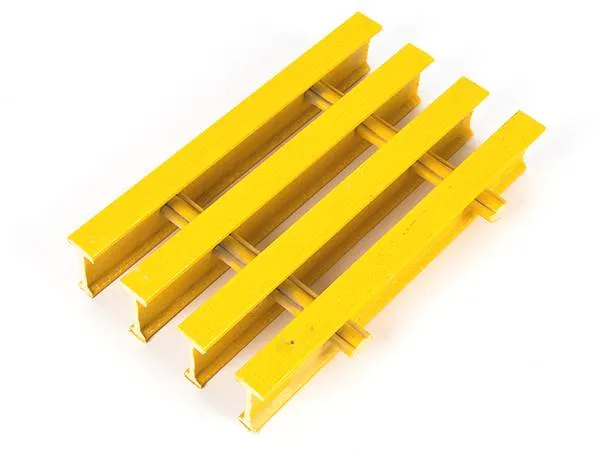

I-Bar Pultruded Grating

T-Bar Pultruded Grating

High load bar grating

Available Bearing Bar Type

Smooth surface

Gritted surface

Corrugated Surface

Convex surface

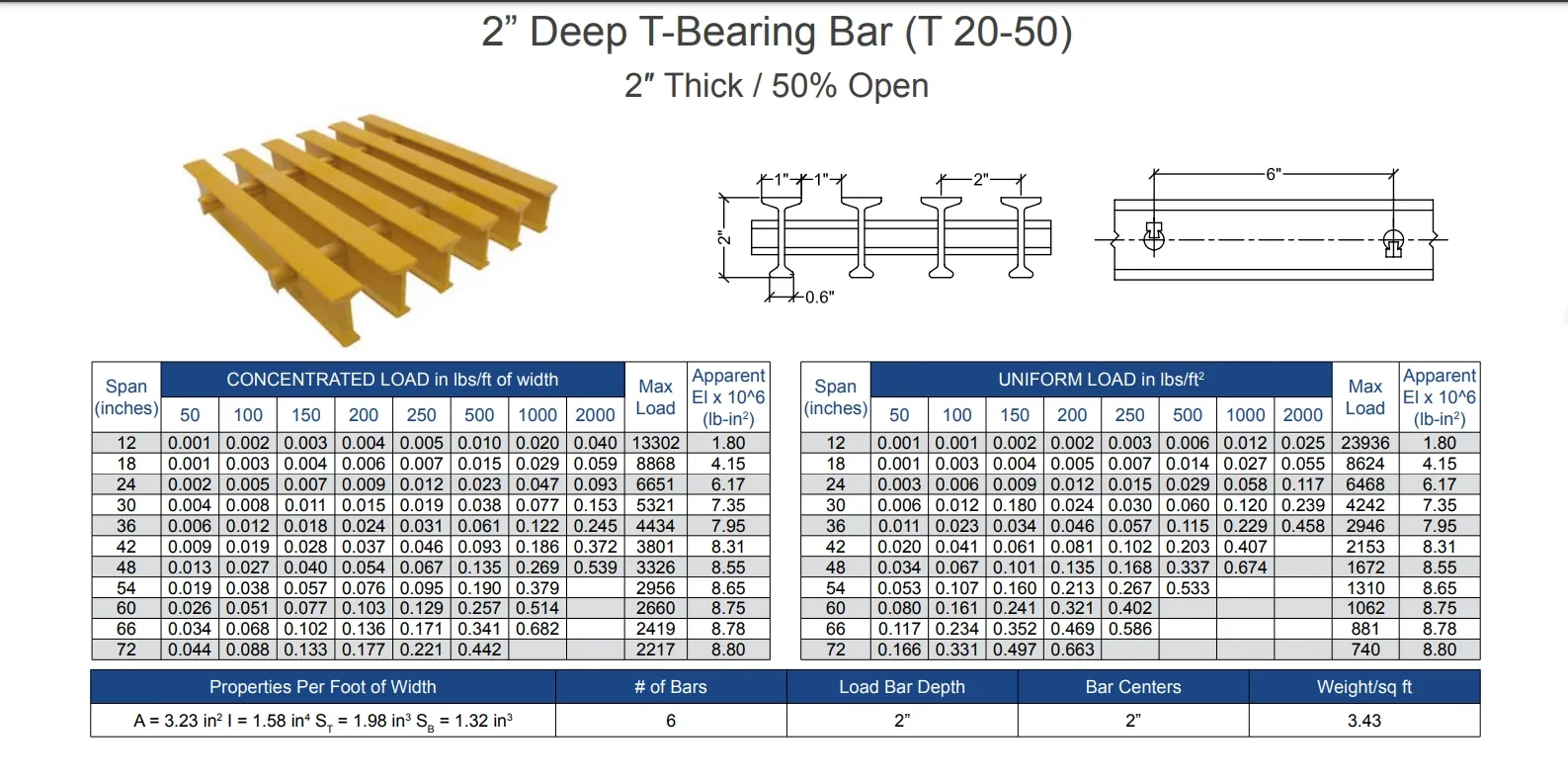

Product Specifications

Your satisfaction is our priority. We tailor our services to meet your unique needs. Quality and excellence are our standards.

Contact us for more information!

FAQ

What is pultruded fiberglass grating?

Pultruded fiberglass grating is a composite material made by pulling glass fibers and resin through a heated die to form a strong, corrosion-resistant grid used for flooring, walkways, and platforms.

What are the main advantages of pultruded fiberglass grating?

It offers high strength, corrosion resistance, lightweight design, low maintenance, non-conductivity, and fire-retardant properties, making it ideal for harsh environments.

How does pultruded grating differ from molded grating?

Pultruded grating is made through a continuous pulling process, resulting in higher stiffness and strength for longer spans, while molded grating is formed in a mold, offering more uniform strength in all directions.

What types of resin are used in pultruded fiberglass grating?

Common resins include isophthalic polyester for moderate corrosion resistance, vinyl ester for superior chemical resistance, and phenolic for enhanced fire and smoke performance.

What industries commonly use pultruded fiberglass grating?

It is widely used in chemical processing, marine, oil and gas, water treatment, manufacturing, and transportation due to its durability and corrosion resistance.

Can pultruded fiberglass grating support heavy loads?

Yes, it is designed for high load-bearing capacity, with options like heavy-duty versions suitable for vehicles such as forklifts or trucks.

Is pultruded fiberglass grating slip-resistant?

Yes, many products feature a gritted surface or coarse texture to enhance slip resistance, improving safety in wet or oily conditions.

What are the typical dimensions of pultruded fiberglass grating panels?

Standard panel sizes include widths of 3, 4, or 5 feet and lengths of 8, 10, or 20 feet, with thicknesses ranging from 1 to 2 inches, depending on the application.

Is pultruded fiberglass grating fire-resistant?

Many options are fire-retardant, with some meeting standards like ASTM E84 Class 1 (flame spread of 25 or less) or higher fire safety requirements for specific industries.

How is pultruded fiberglass grating installed?

It can be easily cut and installed using standard tools, with options for clip or fastener systems to secure panels to supports, requiring minimal maintenance post-installation.

What our happy clients say:

"Quality Beyond Expectation,thanks so much!"

- I purchased your company's fiberglass grating products, and the quality is truly outstanding! I had tried other brands before, but their products didn't match the sturdiness and durability of yours. Your grating not only looks exquisite but also stands the test of time, meeting all my expectations. I would wholeheartedly recommend it to others as one of the best fiberglass gratings I've come across.

- -----Alice Howard

- Engineering Manager