Kind Hold Products

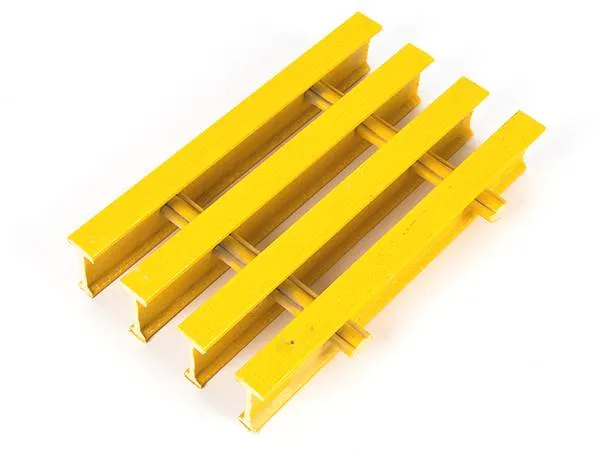

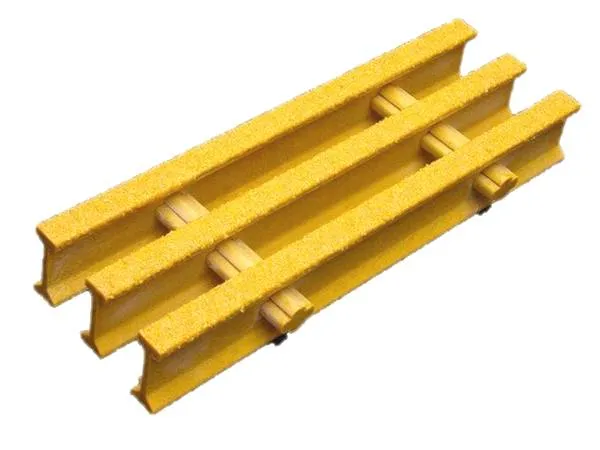

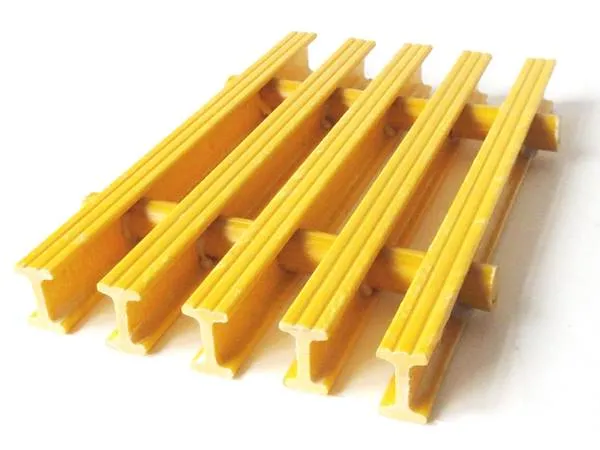

SUPERSPAN MOLDED FIBER GLASS GRATING

Your trusted provider of Fiber Grating solutions

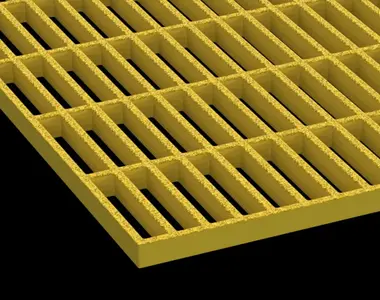

SUPERSPAN GRP GRATING

Superspan grp gratings are used for applications where high loads and spans are needed.

Our fibreglass gratings are corrosion resistant and a durable alternative to steel and plastic gratings.

Other advantages include electrical insulation, high strength and low weight.

Fibreglass gratings are suitable for use in aggressive environments such as offshore, in chemical industrial settings and cooling towers. All gratings have high slip-resistance factor R13 according to BGR 181.

GRP Grating Features

With over a decade of dedicated experience, we have been committed to delivering highly professional molded fiberglass grating technology products.

We understand that professionalism and experience are the keys to success, and they are at the core of our foundation.

Higher loads

Higher loads and longer span than molded grating.

Corrosion resistance

Excellent chemical and harsh condition resistance.

Lightweight

1/3 lighter than steel grating with the same load ability.

Extended life

The coated resin surface increases resistance to chemical corrosion and continuous UV exposure.

Anti-slipping

Gritted, corrugated or convex surface for safe access.

Easy fabrication

Lightweight structure is easy to fabricate by simple hand tools.

Flame retardant

UV inhibitor for UV resistant and fire retardant..

Stability

Higher loads and corrosion resistance for maximum stability.

Our GRP Gratings

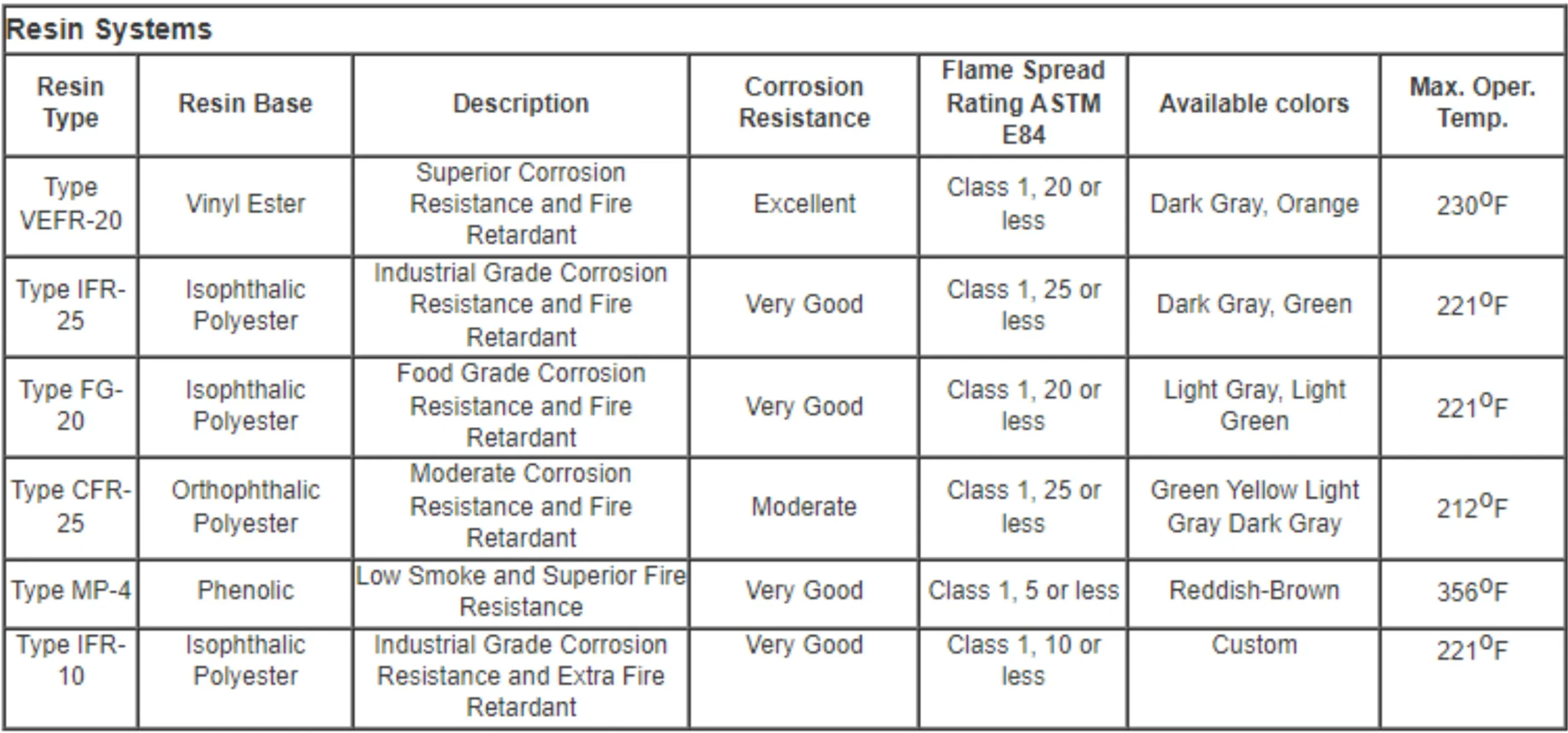

Available Resin

Type of GRP Gratings

- IFR. Isophthalic polyester resin system supplies the most economical and widely used type.

- VFR. Vinyl ester resin system provides high hardness and the highest corrosion resistance.

- EP. Epoxy resin supplies the best insulating property for electric power plants.

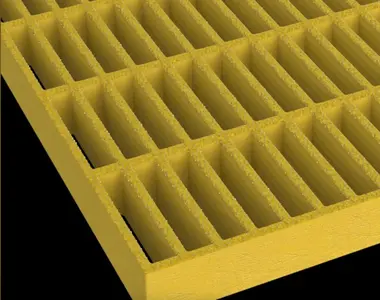

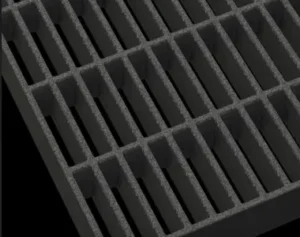

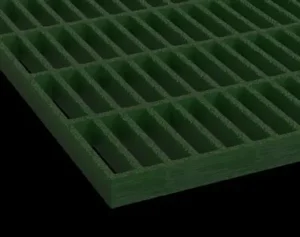

Available Bearing Bar Type ofGRP Gratings

Smooth surface

Gritted surface

Corrugated Surface

Convex surface

Need Whole Loadtable?

Please Contact Us Via The Table!

What is the raw materials of GRP Gratings?

Fiberglass Grating Resin of Fiberglass Grating

All fiberglass grating is using high-quality resin, so that the FRP we produce not only has good stability to a variety of low-concentration acid, alkali, salt media and solvents, but also has good resistance to the effects of atmosphere, seawater and microorganisms.

Fiberglass Yarn of Fiberglass Grating

Using alkali-free yarn. R2O content is less than 0.8%; Its chemical stability, electrical insulation properties, and strength are all very good.

Resin Color Paste of Fiberglass Grating

Good weather resistance, bright colors, not easy to fade over time.

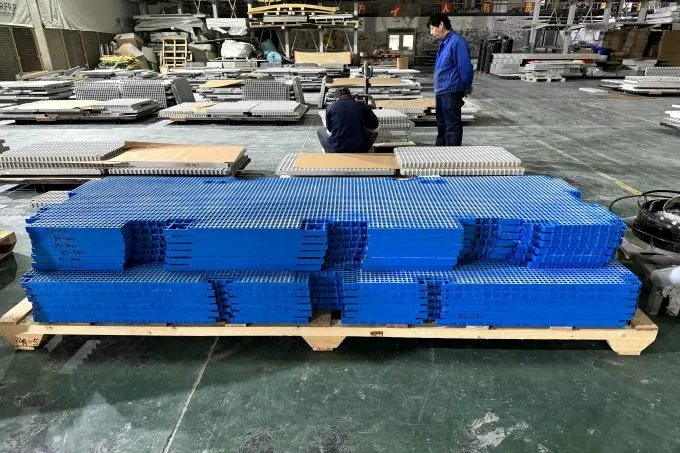

GRP Gratings Manufacture Capability

Mold Design

Cut To Custom Size

Mix Raw Materials

Inspection before Warehousing

Molding production

Packaging Before Shipping

How We Control

The Quality Of GRP Gratings

Raw Material Testing

Control quality from the source to ensure that the fiberglass grating produced meets the standards required by customers.

Test The Load Ability

Random inspections are conducted during the production process to ensure that each batch of FRP gratings meets the load-bearing requirements.

Inspect before Shipping

We adopt the method of inspecting every piece to ensure that the products exported to the customer’s country meet the quality standards.

Our Customized Services of GRP Gratings

Customized according to environment

Fireproof, anti-slip, anti-UV. Tell us your usage environment and we will choose the right material and customize it for you.

Cut according to drawing

Cut it to the size you require according to the drawings and mark it with numbers to facilitate immediate installation.

Color customization

High-quality color paste will be selected according to your color requirements to ensure that it does not fade over the years.

Frequently Asked Questions

A: Requesting a quote for bulk orders is easy. Fill out our inquiry form, and our dedicated team will get back to you with competitive pricing tailored to your business needs. exercitation.

A: Yes, we specialize in custom solutions for B2B clients. Contact us with your project requirements, and we’ll work closely with you to meet your unique specifications. exercitation.

A: We offer flexible payment and credit terms for our B2B partners. Get in touch, and we’ll discuss payment options that suit your business. exercitation.

A: Our efficient supply chain and logistics operations are tailored to meet the demands of B2B clients. We take pride in delivering orders on time and ensuring a seamless process. exercitation.

A: Absolutely! We understand the importance of product evaluation. Contact us to request samples, and we’ll arrange for them to be sent to your business.

What our happy clients say:

"I must say, the quality is top-notch."

- I recently ordered fiberglass grating from your company for an industrial application, and I must say, the quality is top-notch. These gratings are robust, corrosion-resistant, and they meet all the required standards. I appreciate the reliability and durability of your products, which are crucial for our industrial needs. I highly recommend your fiberglass gratings to anyone seeking high-quality solutions.

- -----Ann Smith

- Engineering Manager

Frequently Asked Questions

How to cut fiberglass gratings?

Cutting fiberglass grating requires the use of suitable tools, such as

Diamond blades, which are well-suited for cutting Fiberglass Grating because other tools can become dull quickly and need replacing more frequently.

After the cutting process has finished, it is recommended to treat the cut areas of the Fiberglass Grating with a finishing spray.