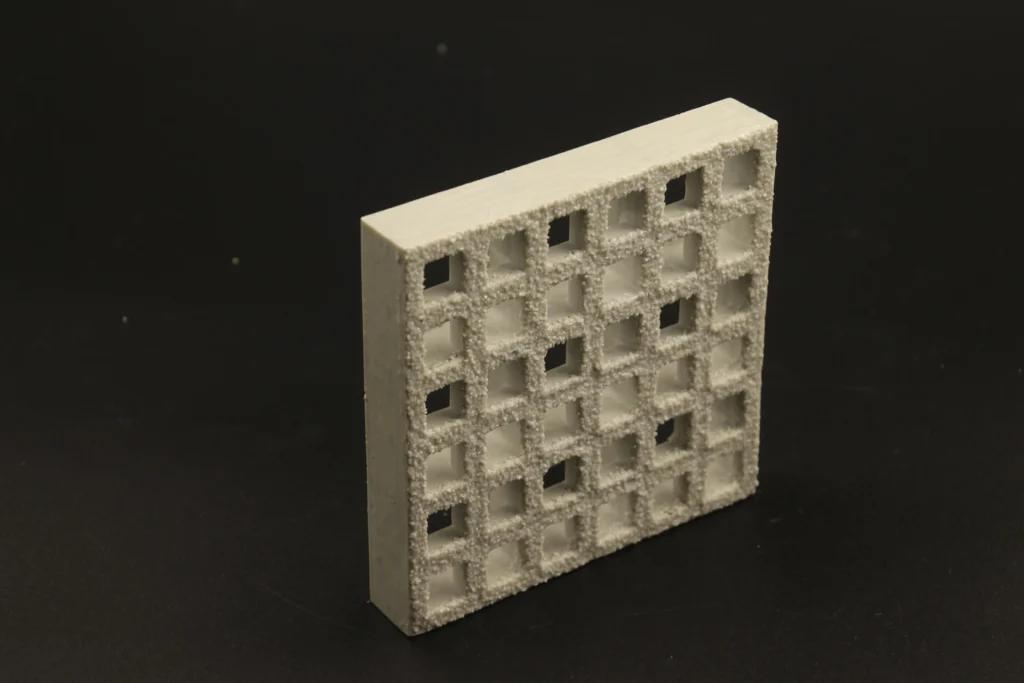

Micro Mesh grating

Micro-Mesh grating finds application in various settings such as docks, piers, boat lifts, and decks.

The panel sizes are 4′ x 12′, featuring a square mesh opening of 3/4″ on the top surface. Additionally, it is utilized in the vicinity of pools, marinas, waterparks, and other public recreational areas.

Micro-Mesh exhibits excellent UV resistance, providing a comfortable surface for bare feet while maintaining durability due to its high strength to weight ratio.

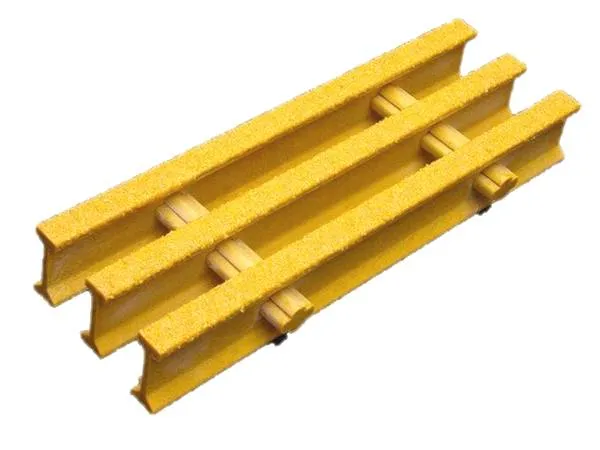

26x26 (Top) / 52x52 (Bottom)Square Grid

38mm Thick / 60% Open

Detail Specifications of Micro Mesh grating

Loadtable Of Micro Mesh grating

Concentrated Load in KG/M of Width

Uniform Load in KG/M²

Frequently Asked Questions

What is the load carrying capacity of Micro Mesh grating?

In terms of strength, fiberglass grating can rival steel. Pultruded fiberglass grating indeed offers higher strength but comes with additional advantages that steel cannot match. For instance, while fiberglass grating is rigid, it is a more flexible material than steel.

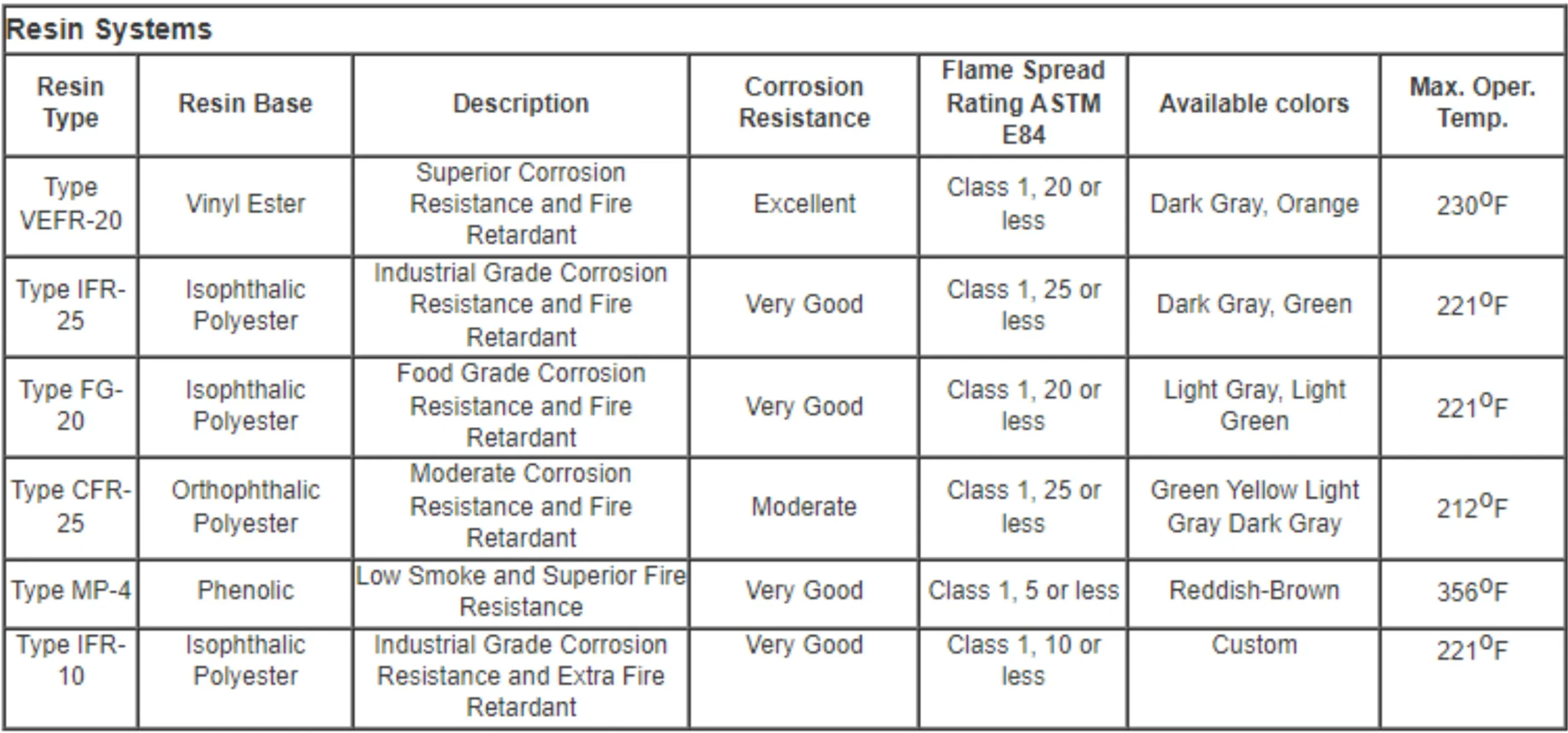

Available Resin Type of Micro Mesh grating

- IFR. Isophthalic polyester resin system supplies the most economical and widely used type.

- VFR. Vinyl ester resin system provides high hardness and the highest corrosion resistance.

- EP. Epoxy resin supplies the best insulating property for electric power plants.

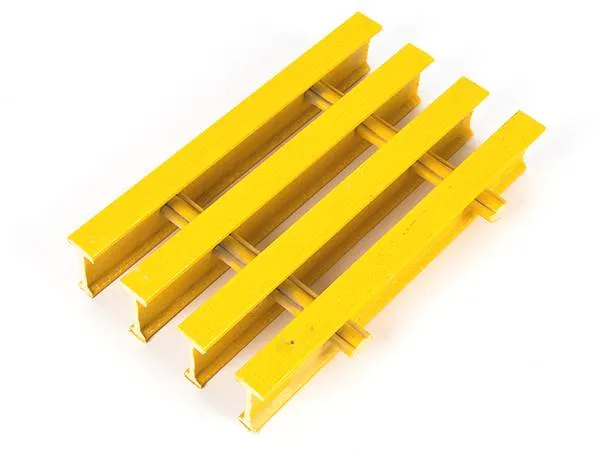

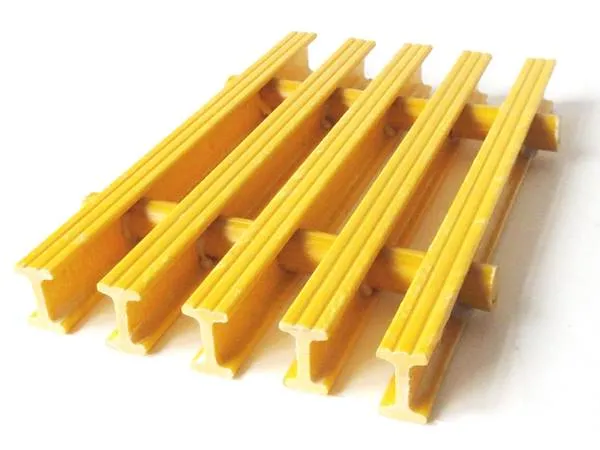

Available Surface Type of Micro Mesh grating

Smooth surface

Gritted surface

Corrugated Surface

Convex surface

Custom Colors of Micro Mesh grating

As proprietors of our factory, we have the capability to produce custom colors matching those on the RAL color chart, offer translucent grating for architecturally pleasing aesthetics, and create bespoke panel sizes tailored for large-scale, repetitive projects.

What our happy clients say:

"I must say, the quality is top-notch."

- I recently ordered fiberglass grating from your company for an industrial application, and I must say, the quality is top-notch. These gratings are robust, corrosion-resistant, and they meet all the required standards. I appreciate the reliability and durability of your products, which are crucial for our industrial needs. I highly recommend your fiberglass gratings to anyone seeking high-quality solutions.

- -----Ann Smith

- Engineering Manager

Scenes To Be Used of Micro Mesh grating

Offshore Wind Power Micro Mesh grating

Chemical industry Micro Mesh grating

Automotive Industry Micro Mesh grating

Oil Drilling Platform Micro Mesh grating

Water Industry Micro Mesh grating

Food and Beverage Industry Micro Mesh grating

What is the raw materials of Micro Mesh grating?

Fiberglass Grating Resin of Micro Mesh grating

All fiberglass grating is using high-quality resin, so that the FRP we produce not only has good stability to a variety of low-concentration acid, alkali, salt media and solvents, but also has good resistance to the effects of atmosphere, seawater and microorganisms.

Fiberglass Yarn of Micro Mesh grating

Using alkali-free yarn. R2O content is less than 0.8%; Its chemical stability, electrical insulation properties, and strength are all very good.

Resin Color Paste of Micro Mesh grating

Good weather resistance, bright colors, not easy to fade over time.

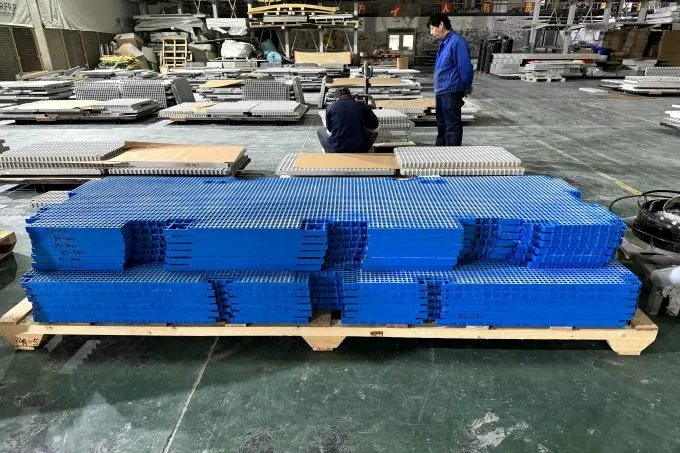

Fiberglass Grating Manufacture Capability of Micro Mesh grating

Mold Design

Cut To Custom Size

Mix Raw Materials

Inspection before Warehousing

Molding production

Packaging Before Shipping

Container Packaging

For container packaging, wooden pallets or iron pallets are used, and one end of the pallet is equipped with pulleys to facilitate unloading.

LCL Package

We also use the tightest packaging for LCL cargo to ensure the safety of the goods in the container and the convenience of loading and unloading.

Our Customized Services

Customized according to environment

Fireproof, anti-slip, anti-UV. Tell us your usage environment and we will choose the right material and customize it for you.

Cut according to drawing

Cut it to the size you require according to the drawings and mark it with numbers to facilitate immediate installation.

Color customization

High-quality color paste will be selected according to your color requirements to ensure that it does not fade over the years.

After Sale Service of FRP Mini Mesh Grating

Every piece meets the standards, and every piece makes you feel at ease

Each fiberglass grating will be inspected before shipment to ensure product quality.

But we still guarantee to replace any goods found to be defective and reported within two (02) months after receipt by the client.

Our Happy Clients!

Frequently Asked Questions

A: Requesting a quote for bulk orders is easy. Fill out our inquiry form, and our dedicated team will get back to you with competitive pricing tailored to your business needs. exercitation.

A: Yes, we specialize in custom solutions for B2B clients. Contact us with your project requirements, and we’ll work closely with you to meet your unique specifications. exercitation.

A: We offer flexible payment and credit terms for our B2B partners. Get in touch, and we’ll discuss payment options that suit your business. exercitation.

A: Our efficient supply chain and logistics operations are tailored to meet the demands of B2B clients. We take pride in delivering orders on time and ensuring a seamless process. exercitation.

A: Absolutely! We understand the importance of product evaluation. Contact us to request samples, and we’ll arrange for them to be sent to your business.

What our happy clients say:

"I must say, the quality is top-notch."

- I recently ordered fiberglass grating from your company for an industrial application, and I must say, the quality is top-notch. These gratings are robust, corrosion-resistant, and they meet all the required standards. I appreciate the reliability and durability of your products, which are crucial for our industrial needs. I highly recommend your fiberglass gratings to anyone seeking high-quality solutions.

- -----Ann Smith

- Engineering Manager

Frequently Asked Questions

How to cut the molded fiberglass gratings?

Cutting fiberglass grating requires the use of suitable tools, such as

Diamond blades, which are well-suited for cutting Fiberglass Grating because other tools can become dull quickly and need replacing more frequently.

After the cutting process has finished, it is recommended to treat the cut areas of the Fiberglass Grating with a finishing spray.

Try the products “Quality Beyond Expectations”

PICK UP THE PHONE AND GIVE US A CALL TODAY!

Contact Us For More Information And Free Samples

About FRP Mini Mesh Grating

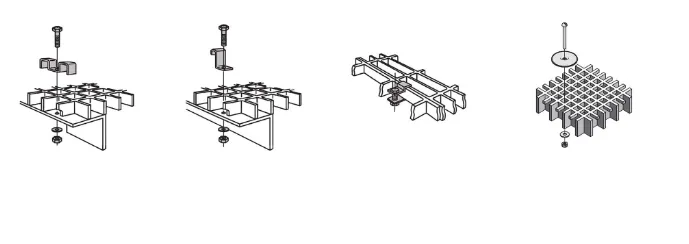

Installation Guidelines

FRP grate panels boast swift and straightforward installation, typically necessitating attachment to supports using specialized stainless steel clips designed for fiberglass grating. These clips also serve to connect panels together seamlessly.

Additionally, it’s crucial to observe safety protocols when cutting and handling fiberglass grating, along with adhering to installation guidelines for fiberglass panels utilized in dock decking and boardwalk applications.