- Home

- »

- Fibergrating's Blog

- »

- The Fire Resistant Benefits of Phenolic Resin in Fiberglass GratingsIntroduction

Table of Contents

Introduction

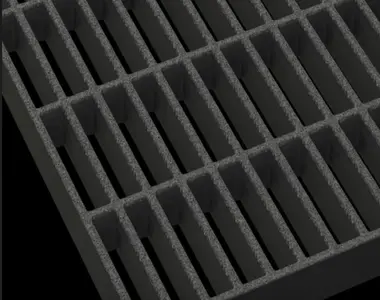

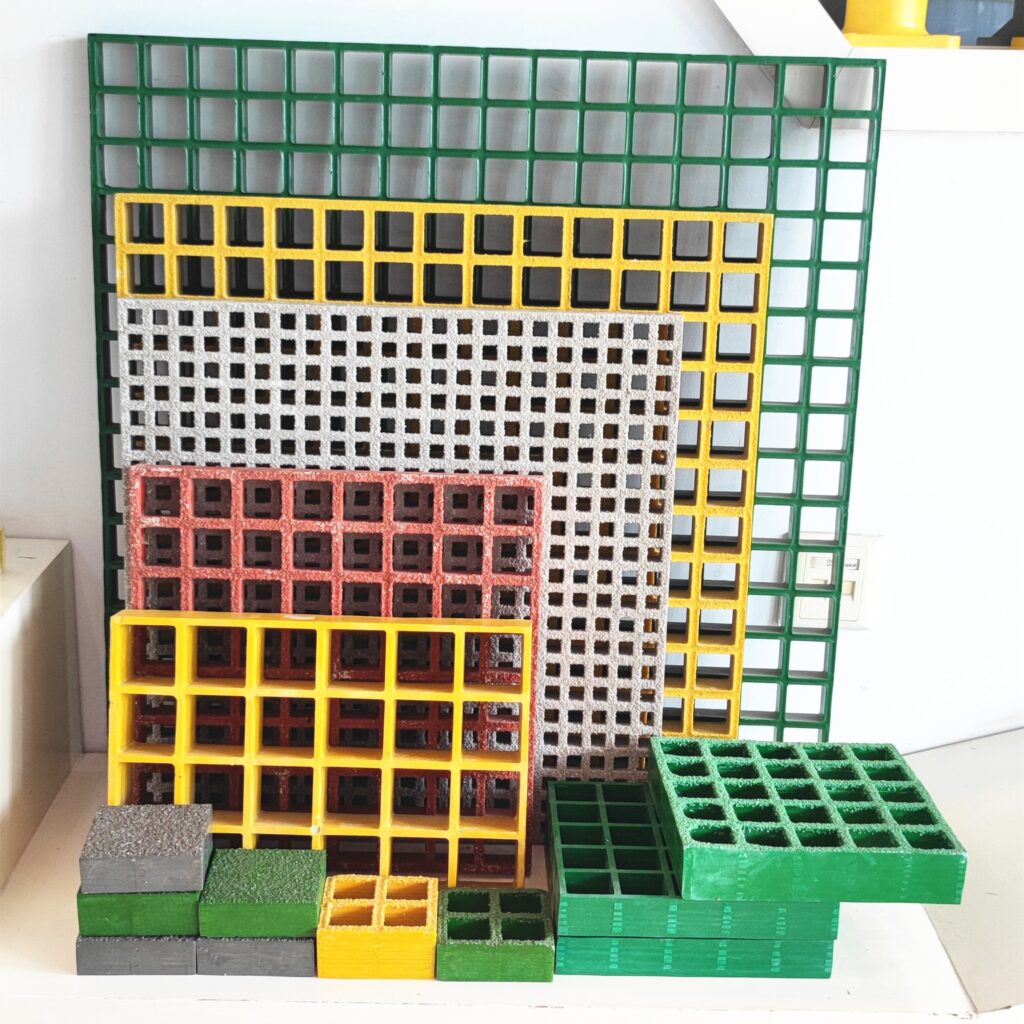

Fiberglass gratings are widely used in various industrial and infrastructure applications due to their resistance to corrosion, lightweight properties, and ease of installation. However, in high-temperature and fire-prone environments like oil refineries, power stations, and tunnels, standard fiberglass gratings may fall short in terms of thermal and fire resistance. This is where fiberglass gratings made with phenolic resin present a clear benefit.

What is Phenolic Resin?

Phenolic resin is a thermosetting polymer produced from the chemical reaction of phenol and formaldehyde. Its distinct chemical composition grants phenolic resin outstanding heat and flame resistance. The highly crosslinked molecular structure of phenolic resin enables it to endure extreme temperatures without melting or emitting toxic fumes, making it ideal for applications where fire safety is critical.

Advantages of Phenolic Resin for Fiberglass Gratings

Phenolic resin’s fire-resistant properties offer several advantages when used in fiberglass gratings:

Superior Fire Retardancy and Heat Resistance:

Fiberglass gratings made with phenolic resin maintain their structural strength and load capacity even when exposed to high heat and flames, preventing disastrous failures during fires.

Compliance with Strict Safety Standards:

Phenolic resin gratings meet rigorous fire safety standards, such as ASTM E-84 for surface burning characteristics and NFPA 130 for transportation tunnels, ensuring they are safe for use in high-risk settings.

Consistent Performance Under Extreme Heat:

Unlike other resins that may melt, soften, or emit harmful fumes when exposed to high temperatures, phenolic resin gratings keep their mechanical properties and resist chemicals even at temperatures over 1000°F (538°C).

Low Smoke and Toxicity:

Phenolic resin has a low smoke density and toxicity when exposed to fire, making it safer in environments where smoke inhalation can pose a severe risk, such as in enclosed spaces like tunnels or underground facilities.

Long Term Durability and Low Maintenance:

Phenolic resin fiberglass gratings have high durability and require minimal maintenance due to their resistance to heat, chemicals, and environmental factors. This results in lower overall maintenance costs and a longer lifespan, providing significant economic benefits.

Key Applications for Phenolic Resin Fiberglass Gratings

The exceptional fire and thermal resistance of phenolic resin fiberglass gratings make them suitable for several safety-critical applications, including:

Oil and gas platforms and refineries;

Power plants, including nuclear and fossil fuel facilities;

Transportation infrastructure like airports, tunnels, and bridges;

Chemical processing plants and other industrial sites;

Marine and Offshore Structures: Phenolic resin gratings are ideal for offshore oil rigs, ship decks, and other marine environments where exposure to harsh chemicals, saltwater, and potential fire hazards are common;

Public Buildings and Institutions: They are used in public buildings, schools, hospitals, and other institutions where fire safety regulations are stringent, ensuring safe evacuation routes and overall safety during a fire emergency.

Performance Characteristics

Phenolic resin fiberglass gratings offer remarkable mechanical, thermal, and chemical resistance. They typically exhibit a flexural strength of 35,000 psi (241 MPa) and can tolerate continuous exposure to temperatures up to 400°F (204°C). These gratings also resist a broad range of corrosive chemicals, making them ideal for use in harsh industrial settings.

Fabrication and Installation Considerations

While phenolic resin fiberglass gratings have similar fabrication and installation requirements to standard fiberglass gratings, there are unique considerations. Because phenolic resin is a thermoset, it cannot be easily modified or repaired on-site, requiring meticulous planning during the design and installation stages. Specialized cutting and drilling methods may also be necessary to ensure proper fitting.

Conclusion

For applications where fire resistance and thermal performance are crucial, phenolic resin fiberglass gratings provide a significant advantage over traditional resins. With their exceptional heat and flame resistance, phenolic resin ensures the structural stability and safety of fiberglass gratings in demanding environments, making them an excellent choice for various industrial and infrastructure projects.

Contact Us

For industries where fire safety, durability, and low maintenance are critical, phenolic resin fiberglass gratings offer unparalleled advantages. Contact us today to learn more about how our high-quality phenolic resin gratings can enhance safety and performance in your specific applications.

Our team of experts is ready to provide you with customized solutions to meet your exact requirements.

Comments

Frequently Asked Question

Phenolic resin has a highly crosslinked molecular structure that allows it to withstand extreme temperatures without melting or emitting toxic fumes. This makes phenolic resin fiberglass gratings highly fire-resistant, maintaining structural integrity and safety even in severe fire conditions.

Yes, phenolic resin fiberglass gratings are highly suitable for outdoor use. They offer excellent resistance to corrosion, chemicals, UV exposure, and harsh environmental conditions, making them ideal for applications in marine environments, refineries, and other outdoor installations.

Phenolic resin gratings meet several stringent fire safety standards, including ASTM E-84 for surface burning characteristics and NFPA 130 for use in transportation tunnels. Compliance with these standards ensures that they can be safely used in high-risk environments such as oil refineries, power plants, and public infrastructure.

Due to their thermoset nature, phenolic resin gratings are not easily modified or repaired on-site. Specialized cutting and drilling techniques are required, and careful planning is necessary during the design and installation phases to ensure a proper fit. It is recommended to consult with experts for precise customization and installation.